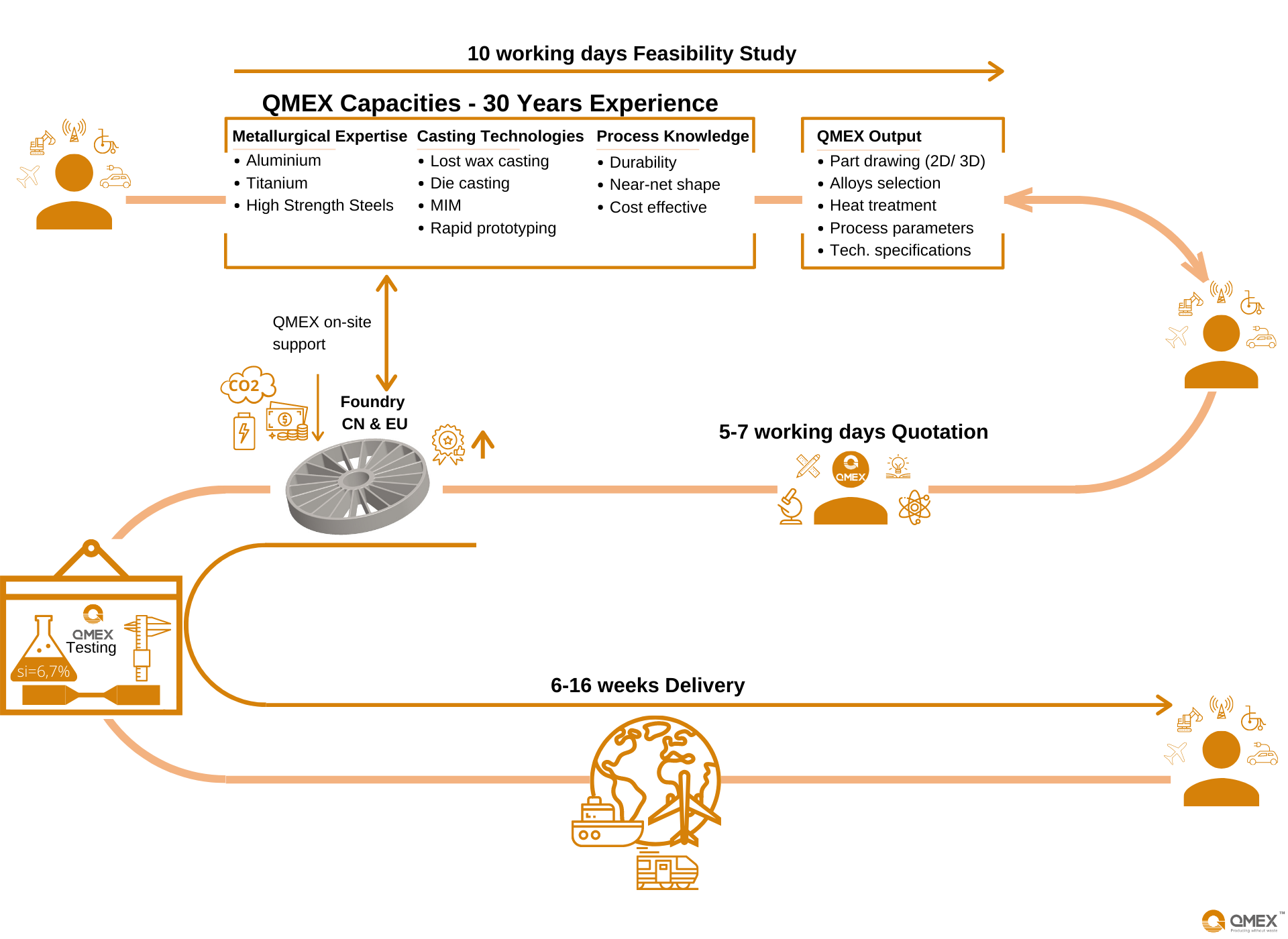

The QMEX method is to produce durable castings to ensure they have a prolonged lifetime. Furthermore, all materials are constantly to be recycled for new cast parts, which means these parts can easily be recycled during the secondry process while producing lesser CO2 and using energy.

Our proficient cast parts CAD designers, metallurgists, process engineers, and R&D department are fully engaged to offer you climate-friendly one-stop-shop solutions. In addition to achieving low-emission and emission-free casting process, our new method has also a positive impact on the material properties of the castings.

Your Key Benefits

Energy efficiency

Energy efficiency

Costs and time-saving

Costs and time-saving

Low emissions

Low emissions

Lightweight and high strength alloys

Lightweight and high strength alloys

Right

materials choice prolong operating life

Right

materials choice prolong operating life

Minimizing

waste during the casting process

Minimizing

waste during the casting process

Innovative

materials are easy to recycle without loss of quality

Innovative

materials are easy to recycle without loss of quality

Cast

parts (re)design with high dimensional accuracy and high complexity

Cast

parts (re)design with high dimensional accuracy and high complexity

Our engineering team has sophisticated knowledge in mould filling and solidification of heat and wear-resistant materials, that resist high-temperature corrosion with a prolonged operating life compared to conventional steels, which is most suitable for hostile environments that are difficult to maintain. By giving you the best possible casting design, we ensure that you can fulfill the most demanding tasks while saving costs, boosting productivity, and achieving optimal efficiency, which provides substantial business value for you.

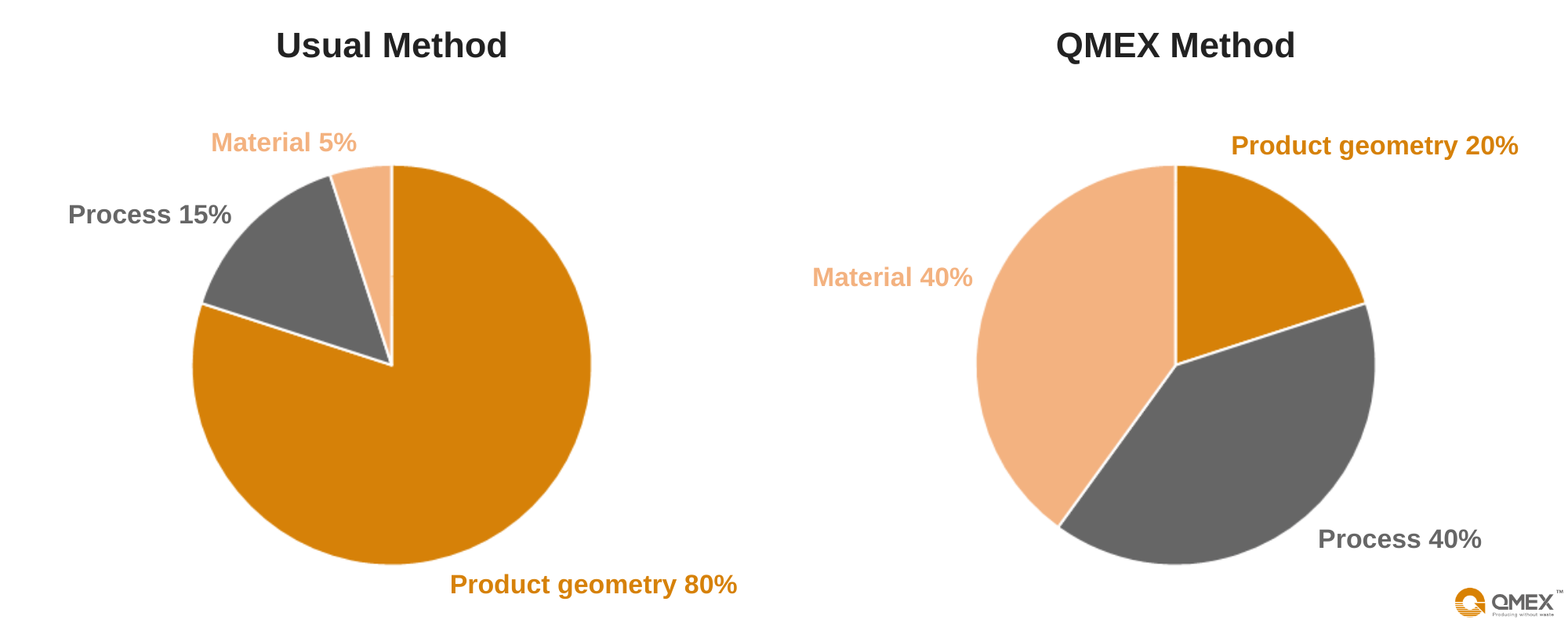

To achieve higher dimensional accuracy, QMEX emphasizes the interaction between the casting process parameters and materials. By adjusting the alloy composition and casting process, it is more feasible to meet the functional requirements specified for the product, such as tight tolerances or optimal mechanical (strength vs toughness) and physical (conductivity) properties.

+31 (0) 570 219 900

Munsterstraat 2F

7418 EV Deventer

The Netherlands

info@qmextechnology.com

© 2019 Qmex Technology B.V. All Rights Reserved.

Site by:GreatGoal