Although operations are well-defined, they usually don’t go as planned in the actual casting process. When that occurs, limited and incomplete process registrations can only partially show you what has happened, leaving engineers or operators occupied with searching relevant process information to find the root cause and relying on their intuition and experience solving the issue. However, an objective look at the underlying process is rarely taken into account. We are here to help you:

The first action we’re going to take is to gain deep insight into the actual flow of your manufacturing processes, which is used for finding causes of process inefficiencies, exceptions, unusual transactions, bottlenecks, deviations etc.

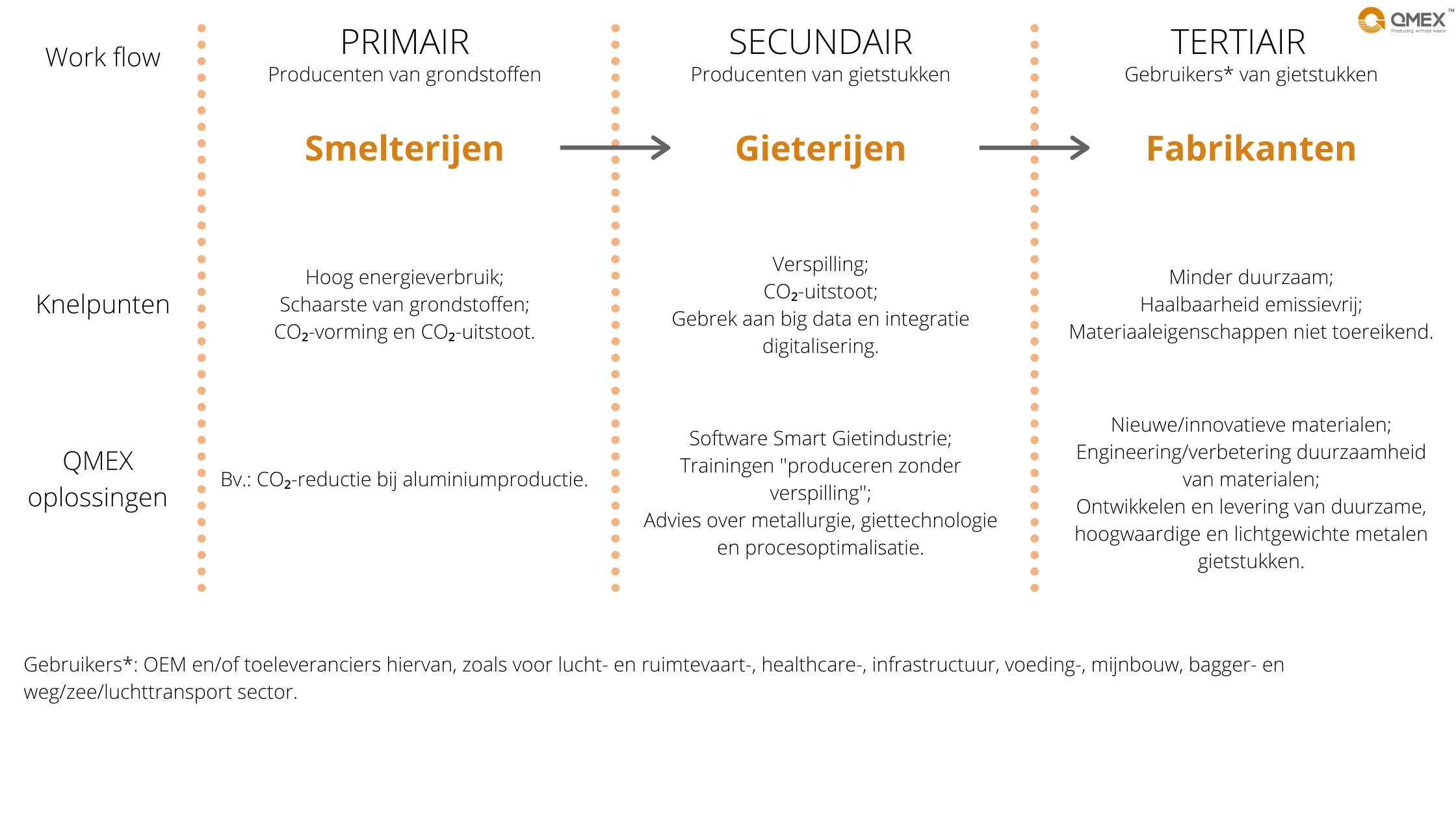

We have more than 30 years of high-tech experience in high-performance lightweight metals and three major advanced casting technologies, particularly die casting, lost wax casting, and MIM in the top sectors. The main objective of our consultancy service is to develop tailored environmental solutions to your casting problems, such as shrinkage, porosities, and excessive finishing, etc.

By applying the QMEX ''Producing Without Waste''-method in the casting process together with our Software Smart Casting Industry, we help you to cut off unnecessary processing steps, root out quality faults, improve the reliability, and the value of your products. Simple is Beautiful!

Our engineering team has sophisticated knowledge in metallurgy, simulation of mold filling and solidification, which will be giving you the best possible casting design and casting process design. We ensure you fulfill the most demanding tasks in the casting process while saving costs, reducing wastes, boosting productivity, achieving optimal efficiency, which will be resulting in substantial business value for you.

+31 (0) 570 219 900

Munsterstraat 2F

7418 EV Deventer

The Netherlands

info@qmextechnology.com

© 2019 Qmex Technology B.V. All Rights Reserved.

Site by:GreatGoal